Whiskey distillation is often perceived as a mysterious craft, overshadowed by the allure of the final product. However, the techniques and methods used in distillation are what give each whiskey its unique character and complexity. This intricate process sets whiskey apart in the vast world of spirits, offering a distinct experience that distinguishes each type of whiskey as a category in its own right.

Key extraction methods in whiskey distillation include Pot Still Distillation and Column Still Distillation, each known for their specific techniques and resulting flavors. The choice between these methods also influences the production of various whiskey types, such as Single Malt, Grain Whiskey, and Bourbon. Diving deeper, each extraction method presents its own set of advantages, operational processes, and impacts on the flavor profile.

The following sections will explore these aspects in detail, providing a richer understanding of the methods behind whiskey distillation and what makes it a revered craft worldwide.

What are the primary extraction methods used in whiskey distillation?

The primary extraction methods in whiskey distillation are pot still distillation and column still distillation. Pot still distillation is a batch process that uses copper pot stills, offering a traditional approach that enhances flavor complexity. Column still distillation, on the other hand, is a continuous process utilizing fractionating columns, known for its efficiency and ability to produce a consistent quality spirit.

Each method has its own unique impact on the whiskey’s flavor and production characteristics.

Pot still distillation

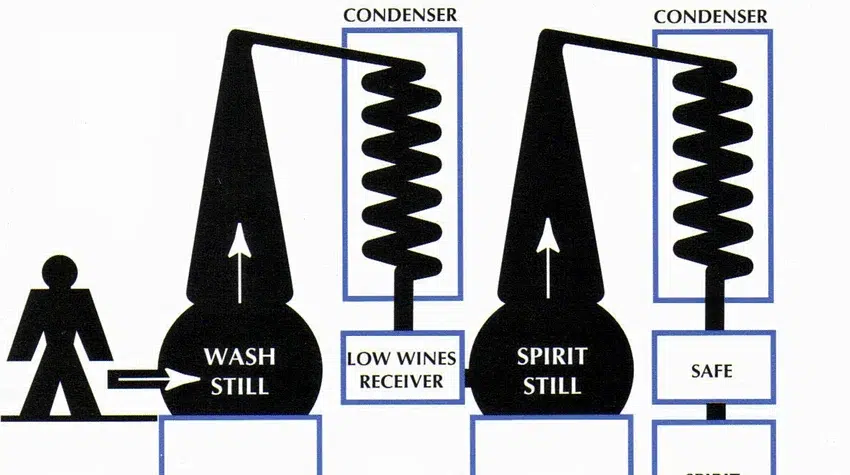

Pot still distillation is a traditional method that operates in a batch process. It involves heating the fermented mash in a copper pot still to produce vapor, which is then condensed to collect the distilled liquid. This method is known for producing whiskey with a richer flavor and more complex character due to the interaction with the copper and the batch nature of the process.

The slower distillation allows for greater control over the final product’s taste and aroma.

Column still distillation

Column still distillation is a modern method that operates in a continuous process. It uses fractionating columns to separate alcohol from the mash efficiently. This method allows for a higher production rate and more consistent quality in the final product.

The continuous nature of column stills makes them ideal for large-scale whiskey production, offering both efficiency and precision. The design of the columns enables better separation of impurities, resulting in a cleaner spirit.

How does pot still distillation work?

Pot still distillation works by heating a batch of fermented mash in a copper pot still. As the mash heats, alcohol vapor rises and travels through the still’s neck. The vapor then condenses into liquid form as it cools.

This process is repeated multiple times to achieve the desired alcohol concentration. The copper material of the pot still plays a crucial role in removing unwanted sulfur compounds, enhancing the whiskey’s flavor. This method, being a batch process, allows for meticulous control over each distillation run, contributing to a richer and more complex flavor profile.

Batch process

The batch process in pot still distillation involves heating a specific amount of fermented mash in a single run. Each batch is distilled separately, allowing for precise control over the heating and cooling phases. This method ensures that the distiller can closely monitor and adjust each step to achieve the desired flavor and alcohol content.

The batch process is integral to producing whiskey with a richer and more nuanced flavor profile. It provides the flexibility to experiment with different mash compositions and distillation techniques.

Copper pot stills

Copper pot stills are essential in pot still distillation due to their unique properties. Copper reacts with sulfur compounds in the mash, removing these unwanted elements and resulting in a cleaner and smoother spirit. The shape and design of the copper pot still also influence the whiskey’s final character, as they affect the reflux and condensation processes.

Copper’s ability to conduct heat evenly ensures a consistent distillation, contributing to the overall quality and complexity of the whiskey. Additionally, the longevity and durability of copper make it a preferred material for traditional distillation methods.

How does column still distillation work?

Column still distillation operates as a continuous process that efficiently separates alcohol from the fermented mash. The mash is fed into the column still, where it flows downward while steam rises through the column. This interaction causes the alcohol to vaporize and ascend through multiple levels of fractionating columns.

Each level, or plate, in the column facilitates the separation of various compounds. The vapor is then condensed into liquid form at the top of the column. This method allows for a high degree of separation and purification, resulting in a cleaner and more consistent spirit.

The continuous nature of column still distillation makes it ideal for large-scale production, ensuring both efficiency and quality control.

Continuous process

The continuous process in column still distillation allows for the uninterrupted feeding of fermented mash into the still. Unlike batch distillation, this method ensures a steady flow of mash and steam, enabling the distillation to occur without stopping. This continuous operation enhances efficiency and supports large-scale production, as it can handle significant volumes of mash.

The consistent input and output help maintain a uniform quality in the distilled spirit, making it ideal for producing whiskey at an industrial scale. Additionally, the continuous process reduces downtime, increasing overall productivity.

Fractionating columns

Fractionating columns are crucial components of column still distillation. These columns contain multiple levels, or plates, that facilitate the separation of alcohol from the mash. As the mash flows downward and steam rises, the alcohol vaporizes and ascends through the plates.

Each plate acts as a mini-distillation stage, enhancing the purity of the vapor. The design of fractionating columns allows for precise control over the distillation process, resulting in a cleaner and more consistent spirit. The ability to finely tune the separation process makes fractionating columns essential for high-quality whiskey production.

Additionally, the modular nature of these columns allows for adjustments to meet specific production needs.

What are the advantages of pot still distillation?

Pot still distillation offers several advantages, primarily in the realm of flavor development and traditional craftsmanship. This method produces whiskey with a richer flavor and more complex character due to the interaction with copper and the batch nature of the process. The ability to control each distillation run allows for meticulous adjustments that enhance the final product’s taste and aroma.

Additionally, pot still distillation preserves traditional methods, connecting modern whiskey production with its historical roots. This approach is highly valued for creating premium, artisanal whiskeys that stand out for their depth and uniqueness.

Richer flavor

Pot still distillation is renowned for producing whiskey with a richer flavor. The batch process allows for greater control over each distillation run, enabling the distiller to make precise adjustments that enhance the final product’s taste and aroma. The interaction with copper during distillation removes unwanted sulfur compounds, resulting in a smoother and more complex spirit.

This method captures a wide range of flavor compounds, contributing to the whiskey’s depth and character. The slow, deliberate nature of pot still distillation ensures that the final product retains a unique and robust flavor profile.

Traditional methods

Traditional methods are a hallmark of pot still distillation. This technique has been used for centuries, preserving the heritage and craftsmanship of whiskey production. The use of copper pot stills and the batch process connect modern distillers with historical practices, ensuring that each bottle of whiskey carries a piece of its rich history.

These traditional methods are highly valued for their ability to produce premium, artisanal whiskeys that stand out for their authenticity and uniqueness. The commitment to tradition also allows for the preservation of time-honored recipes and techniques, ensuring the continued legacy of classic whiskey styles.

What are the advantages of column still distillation?

Column still distillation offers significant advantages in terms of efficiency and consistency. This method operates as a continuous process, allowing for the uninterrupted production of whiskey, which is ideal for large-scale operations. The use of fractionating columns ensures a high degree of separation and purification, resulting in a cleaner and more consistent spirit.

Column stills can process large volumes of mash, making them highly efficient and cost-effective. Additionally, the ability to maintain precise control over the distillation parameters ensures that the quality of the whiskey remains consistent from batch to batch. This method is particularly suited for producing whiskey types that require a high level of purity and uniformity.

Higher efficiency

Column still distillation is highly regarded for its higher efficiency. The continuous process allows for the uninterrupted flow of mash and steam, making it possible to distill large volumes without the need for frequent stops and starts. This efficiency translates to cost savings and increased production capacity, making it ideal for large-scale whiskey production.

The design of the fractionating columns ensures optimal separation of alcohol from the mash, reducing waste and maximizing yield. Additionally, the ability to maintain a steady production flow minimizes downtime, further enhancing overall efficiency. This method’s ability to handle significant volumes of mash efficiently makes it a preferred choice for industrial distillation.

Consistent quality

Consistent quality is a key advantage of column still distillation. The continuous nature of the process, combined with the precise control offered by fractionating columns, ensures that each batch of whiskey maintains a uniform quality. The ability to finely tune the distillation parameters allows for the consistent removal of impurities, resulting in a cleaner spirit.

This consistency is crucial for brands that require a reliable product profile, ensuring that consumers receive the same high-quality whiskey with every purchase. The method’s precision and control contribute to the production of whiskey with a uniform flavor and purity, meeting the expectations of both producers and consumers. Furthermore, the scalability of column stills allows for consistent quality even as production volumes increase.

What types of whiskey are produced using pot still distillation?

Pot still distillation is primarily used to produce single malt whiskey and Irish pot still whiskey. Single malt whiskey, often associated with Scotland, is made from malted barley and distilled in copper pot stills, resulting in a rich and complex flavor profile. Irish pot still whiskey, on the other hand, is made from a mix of malted and unmalted barley, giving it a distinctive, creamy texture and spicy notes.

These types of whiskey benefit from the traditional methods and meticulous control offered by pot still distillation, which enhances their unique characteristics and depth of flavor.

Single malt whiskey

Single malt whiskey is produced using pot still distillation and is often associated with Scotland. It is made exclusively from malted barley and distilled in copper pot stills. This traditional method contributes to a rich and complex flavor profile, characterized by a wide range of aromas and tastes.

The meticulous control over each distillation run allows for the development of unique and nuanced flavors, making single malt whiskey highly prized among connoisseurs. The aging process in oak barrels further enhances its depth, adding layers of flavor and complexity.

Irish pot still whiskey

Irish pot still whiskey is another type of whiskey produced using pot still distillation. It is made from a mix of malted and unmalted barley, which gives it a distinctive character. The use of copper pot stills in its production results in a whiskey with a creamy texture and spicy notes.

This combination of ingredients and traditional distillation methods enhances the whiskey’s depth and complexity, making it a unique offering in the world of whiskey. Irish pot still whiskey is celebrated for its rich heritage and distinctive flavor profile. The blend of barley types and the careful distillation process create a balanced and flavorful spirit that stands out in the market.

What types of whiskey are produced using column still distillation?

Column still distillation is commonly used to produce grain whiskey and bourbon. Grain whiskey, often used in blends, is made from various grains such as corn, wheat, and barley. The continuous process of column still distillation ensures a clean and consistent spirit, which is ideal for blending.

Bourbon, a type of American whiskey, is made primarily from corn and also benefits from the efficiency and consistency of column still distillation. This method allows for the production of large volumes while maintaining a high level of quality, making it suitable for creating both grain whiskey and bourbon with uniform flavor profiles.

Grain whiskey

Grain whiskey is produced using column still distillation and is often made from a variety of grains such as corn, wheat, and barley. The continuous process of column still distillation ensures a clean and consistent spirit, which is ideal for blending with other types of whiskey. Grain whiskey typically has a lighter flavor profile, making it a versatile component in blended whiskeys.

The efficiency of column stills allows for the production of large volumes of grain whiskey, maintaining a uniform quality that is essential for creating balanced blends. This method is particularly valued for its ability to produce a reliable base spirit that enhances the complexity of blended whiskey products.

Bourbon

Bourbon is a type of American whiskey that is primarily made from corn. It also benefits from the efficiency and consistency provided by column still distillation. The continuous process ensures that bourbon is produced in large volumes while maintaining a high level of quality.

The use of column stills helps achieve a cleaner spirit, which is then aged in new charred oak barrels to develop its distinctive flavor profile. The combination of column still distillation and specific aging requirements results in a bourbon that is both rich and consistent, meeting the standards expected by consumers. This method allows bourbon producers to scale their operations while preserving the unique characteristics that define this popular American whiskey.

How do extraction methods affect the flavor profile of whiskey?

Extraction methods significantly impact the flavor profile of whiskey. Pot still distillation enhances the richness and complexity of flavors due to the interaction with copper and the batch process, which allows for meticulous control over each run. This method captures a wide range of flavor compounds, resulting in a more nuanced spirit.

In contrast, column still distillation produces a cleaner and more consistent spirit by efficiently separating alcohol from impurities through fractionating columns. The continuous process ensures uniform quality, making it ideal for whiskeys that require a high level of purity. The choice of extraction method ultimately shapes the whiskey’s taste, aroma, and overall character.

Influence of copper

The influence of copper is a crucial factor in pot still distillation. Copper reacts with sulfur compounds present in the mash, removing these unwanted elements and resulting in a cleaner and smoother spirit. This interaction enhances the whiskey’s flavor complexity by allowing more desirable compounds to remain in the final product.

Copper’s ability to conduct heat evenly also ensures a consistent distillation process, contributing to the overall richness and depth of the whiskey’s flavor profile. Additionally, the longevity and durability of copper make it an ideal material for traditional distillation methods, preserving the integrity of the spirit over multiple distillation runs.

Impact of reflux

The impact of reflux plays a significant role in both pot still and column still distillation. In pot stills, the shape and design of the still influence the amount of reflux, which affects the concentration of flavors. Higher reflux results in a lighter and more refined spirit, while lower reflux produces a heavier and more robust flavor.

In column stills, fractionating columns create multiple stages of reflux, allowing for precise control over the separation of alcohol and impurities. This results in a cleaner and more consistent spirit, with a well-defined flavor profile. The ability to manage reflux effectively is essential for achieving the desired taste and quality in whiskey.

Effective reflux management allows distillers to fine-tune the spirit’s characteristics, ensuring a balanced and harmonious flavor profile.

What are the key considerations when choosing an extraction method?

When choosing an extraction method for whiskey distillation, several key considerations come into play. The desired flavor profile is paramount, as pot stills produce richer, more complex flavors, while column stills yield cleaner and more consistent spirits. Production scale is another critical factor; pot stills are suitable for smaller, artisanal batches, whereas column stills excel in large-scale, industrial production due to their efficiency.

Cost and efficiency also influence the decision, with column stills offering higher throughput and lower operational costs. Balancing these factors ensures that the chosen method aligns with the distiller’s goals and market demands.

Desired flavor profile

The desired flavor profile is a crucial consideration when choosing an extraction method. Pot still distillation is known for producing whiskey with a richer and more complex flavor, thanks to the interaction with copper and the batch process. This method captures a wide range of flavor compounds, resulting in a more nuanced spirit.

On the other hand, column still distillation yields a cleaner and more consistent spirit, making it ideal for whiskeys that require a high level of purity. The choice between these methods depends on whether the distiller aims for a robust, artisanal whiskey or a refined, consistent product.

Production scale

Production scale is another critical factor in selecting an extraction method. Pot stills are suitable for smaller, artisanal batches, allowing for meticulous control over each distillation run. This makes them ideal for producing premium, small-batch whiskeys with unique characteristics.

In contrast, column stills excel in large-scale, industrial production due to their continuous process and efficiency. They can handle significant volumes of mash, making them perfect for high-volume whiskey production while maintaining consistent quality.

Cost and efficiency

Cost and efficiency also play a significant role in the decision-making process. Column still distillation offers higher throughput and lower operational costs, making it a more cost-effective option for large-scale production. The continuous nature of column stills reduces downtime and increases overall productivity, translating to cost savings.

Pot still distillation, while producing a richer flavor, involves higher labor and time costs due to its batch nature. Distillers must weigh these factors to determine the most economically viable method that aligns with their production goals and market demands.

How do traditional and modern extraction techniques differ?

Traditional and modern extraction techniques in whiskey distillation differ primarily in their equipment used and process control. Traditional methods, such as pot still distillation, employ copper pot stills and operate in batch processes, allowing for meticulous control and the production of rich, complex flavors. Modern techniques, like column still distillation, utilize fractionating columns and a continuous process, enabling higher efficiency and consistency.

These modern methods are designed for large-scale production, offering precise control over distillation parameters and resulting in a cleaner, more uniform spirit. The choice between traditional and modern techniques depends on the desired flavor profile, production scale, and efficiency goals.

Equipment used

Equipment used in traditional and modern extraction techniques varies significantly. Traditional methods rely on copper pot stills, which are known for their ability to enhance flavor complexity through interaction with copper. These stills are typically used in batch processes, allowing for meticulous control over each distillation run.

The craftsmanship and heritage associated with copper pot stills contribute to the unique character of the whiskey produced. In contrast, modern methods utilize fractionating columns, which are designed for continuous operation. These columns enable efficient separation of alcohol from impurities and are ideal for large-scale production.

The advanced design of fractionating columns allows for precise control over the distillation process, resulting in a cleaner and more consistent spirit.

Process control

Process control is another key difference between traditional and modern extraction techniques. Traditional methods, such as pot still distillation, operate in batch processes, which allow distillers to make detailed adjustments during each run. This level of control contributes to the production of whiskey with a rich and complex flavor profile.

The batch process provides the flexibility to experiment with different mash compositions and distillation techniques. On the other hand, modern methods employ a continuous process, particularly in column still distillation. This approach ensures a steady flow of mash and steam, enabling high efficiency and consistent quality.

The continuous process allows for precise control over distillation parameters, ensuring uniformity in the final product while minimizing downtime and increasing overall productivity. The ability to maintain a constant production flow is especially beneficial for meeting large-scale production demands.

What role does the distiller’s expertise play in the extraction process?

The distiller’s expertise is pivotal in the whiskey extraction process, influencing both the flavor and quality of the final product. Skilled distillers excel in managing stills and understanding the nuances of the distillation process, allowing them to make precise adjustments that enhance the whiskey’s character. Their knowledge of flavor development enables them to optimize factors such as temperature control and cut points, ensuring the desired taste profile.

Whether using traditional pot stills or modern column stills, a distiller’s experience and intuition are crucial for achieving consistency and excellence in whiskey production. The ability to troubleshoot and adapt to varying conditions further underscores the importance of a distiller’s expertise in crafting high-quality whiskey.

Skill in managing stills

Skill in managing stills is essential for any distiller. This involves understanding the intricacies of the distillation equipment, whether it’s a traditional copper pot still or a modern fractionating column. A skilled distiller can make precise adjustments during the distillation process, such as controlling the temperature and monitoring the flow rates.

These adjustments are crucial for achieving the desired alcohol concentration and removing impurities. Effective still management ensures that each distillation run produces a high-quality spirit, contributing to the overall excellence of the whiskey. The ability to troubleshoot and adapt to varying conditions further underscores the importance of this skill in maintaining consistency and quality.

Knowledge of flavor development

Knowledge of flavor development is another critical aspect of a distiller’s expertise. This includes understanding how different factors, such as mash composition, fermentation time, and distillation techniques, affect the final flavor profile of the whiskey. A knowledgeable distiller can optimize these factors to enhance specific flavor notes, whether aiming for a rich, complex single malt or a clean, consistent bourbon.

Additionally, understanding the impact of aging and barrel selection further refines the whiskey’s character. This deep knowledge allows distillers to craft whiskeys with distinct and desirable flavor profiles, meeting the expectations of discerning consumers. The ability to predict and control flavor outcomes is essential for producing high-quality whiskey that stands out in a competitive market.

How can one optimize extraction methods for better whiskey quality?

Optimizing extraction methods for better whiskey quality involves precise temperature control and effective cut points management. Maintaining the right temperature during distillation ensures the efficient separation of alcohol from impurities, enhancing the spirit’s purity and flavor. Proper cut points management, which involves selecting the optimal moments to collect different fractions of the distillate, allows for the capture of the best flavors while minimizing unwanted compounds.

By fine-tuning these parameters, distillers can significantly improve the quality and consistency of their whiskey, resulting in a superior final product.

Temperature control

Temperature control is crucial for optimizing whiskey extraction methods. Maintaining the right temperature during distillation ensures the efficient separation of alcohol from impurities. Precise temperature management allows distillers to target specific boiling points, capturing the desired alcohol while leaving behind unwanted compounds.

This meticulous control enhances the purity and flavor of the final spirit. Consistent temperature regulation is essential for producing high-quality whiskey with a well-defined flavor profile. It also helps in achieving uniformity across different batches, ensuring that each bottle meets the same standards of excellence.

Advanced temperature monitoring systems can further improve the precision and reliability of the distillation process.

Cut points management

Cut points management involves selecting the optimal moments to collect different fractions of the distillate. The distillation process is divided into three main parts: the heads, hearts, and tails. The heads contain undesirable compounds and are discarded, while the hearts hold the highest quality alcohol and are retained.

The tails may contain some useful flavors but also unwanted elements. Effective cut points management allows distillers to capture the best flavors while minimizing impurities. By fine-tuning these cut points, distillers can significantly enhance the quality and consistency of their whiskey, resulting in a superior final product.

This practice is essential for achieving the desired taste and aroma, making it a critical aspect of the distillation process. Experienced distillers use their knowledge and intuition to determine the precise cut points, ensuring the optimal balance of flavors in the whiskey.