Whiskey bottling might seem like just another step in the production process, but it’s actually where the magic happens—transforming a spirit that’s been lovingly aged into the final, ready-to-sip masterpiece. From the meticulous filling of each bottle to the artful sealing and labeling, every detail is designed to preserve the rich flavors and aromas that have developed over time. In this article, we’ll take you behind the scenes to explore how tradition, technology, and a commitment to quality come together in the bottling of whiskey, ensuring that every pour is as perfect as the last.

Whiskey Bottling

Whiskey bottling is the culmination of a craft that begins in the field and the distillery, a critical phase where the distilled spirit is meticulously sealed and readied for its journey to enthusiasts. The integrity of whiskey, with its rich tapestry of flavors and aromas, is enshrined during this process, ensuring the distiller’s artistry is conveyed intact to the end consumer. Legal standards dictate meticulous adherence to alcohol content and labeling, while consistency in the product is paramount, offering the same quality experience in every pour. Each step, from the sterilization of vessels to the methodical filling, capping, and dressing of the bottle, is executed with precision, reflecting the distillery’s commitment to excellence. Beyond simple containment, the bottle serves as a vessel of the narrative, its design and labeling offering a prelude to the sensory journey within. Unveiling the nuances of whiskey bottling unveils the confluence of tradition, technology, and stringent quality controls that coalesce to deliver not just a beverage, but a legacy in liquid form.

What is Whiskey Bottling?

Whiskey bottling is the pivotal stage where the spirit transitions from its aging environment into its final, consumer-ready form. This process is crucial for maintaining the whiskey’s integrity and character, which have been carefully cultivated during its maturation period. Precision filling ensures that each bottle contains an exact measure of whiskey, guaranteeing consistency for consumers. The sealing of the bottle is not just a closure but a guardian against oxidation and contamination, preserving the whiskey’s quality and flavor profile.

Accurate labeling is not only a source of information for enthusiasts but also a strict legal requirement, detailing essential information such as alcohol content and geographic origin. Advanced bottling technology enhances the process by promoting cleanliness and streamlining operations, while thoughtful packaging design offers both protection and brand storytelling. Throughout this process, rigorous quality control measures are in place to ensure that each bottle reflects the distillery’s commitment to excellence, readying the whiskey for its journey to connoisseurs around the world.

What is Whiskey Bottling?

Whiskey bottling represents the critical transition of whiskey from its aging casks to the bottle, a process integral to preserving the spirit’s rich flavors and aromas. It is a stage where precision governs the filling of each bottle to ensure uniformity across every batch. The sealing acts as a shield, protecting the whiskey from external elements that could compromise its quality and taste.

Labeling is more than just branding; it’s a compliance measure, providing consumers with essential information like alcohol by volume (ABV) and origin, while adhering to strict regulations. Modern bottling technology plays a pivotal role in maintaining sanitation and improving efficiency, ensuring that the whiskey remains uncontaminated throughout the process. The packaging not only safeguards the whiskey but also serves as a canvas for the brand’s story and identity.

At every step, quality control is paramount, with measures in place to inspect bottle integrity and maintain the high standards expected by both the distillery and the discerning consumer. This meticulous process ensures that when a bottle of whiskey reaches the hands of the enthusiast, it is not merely a drink, but a crafted experience—the distiller’s legacy encapsulated.

Importance of the Bottling Process

The bottling process stands as a critical juncture in whiskey production, pivotal for preserving the spirit’s integrity and flavor profile. It acts as the final defense against quality degradation, ensuring the complex aromas and tastes developed during aging are perfectly captured. Legal compliance is integral at this stage, with stringent regulations governing alcohol by volume (ABV) and mandatory labeling, which distilleries must adhere to.

Moreover, bottling is synonymous with a brand’s consistency promise—a guarantee that each bottle a consumer picks up meets their expectations of excellence. The process encompasses meticulous sanitization, precise filling, and secure sealing, all underpinned by rigorous quality control. These steps collectively ensure that when whiskey leaves the distillery, it not only reflects the brand’s heritage but also delivers a consistent, high-quality experience to aficionados worldwide.

Preserves Whiskey’s Integrity

The bottling phase acts as the custodian of the whiskey’s core identity, meticulously encapsulating the depth of flavors and nuances of aromas. This critical step ensures the purity and essence of the whiskey remain untouched from barrel to bottle, delivering an unblemished experience to the connoisseur.

Ensures Legal Compliance

Bottling also serves as a bastion of regulatory adherence, where alcohol by volume (ABV) and labeling accuracy are rigorously checked against legal standards. This ensures that each bottle not only meets the legal requirements but also upholds the industry’s trust and integrity.

Controls Product Consistency

Consistency is the hallmark of a trusted whiskey brand, and bottling is where this uniformity is achieved. Through precise filling and sealing techniques, bottling ensures that each bottle offers the same richness and quality—a testament to the distillery’s dedication to excellence.

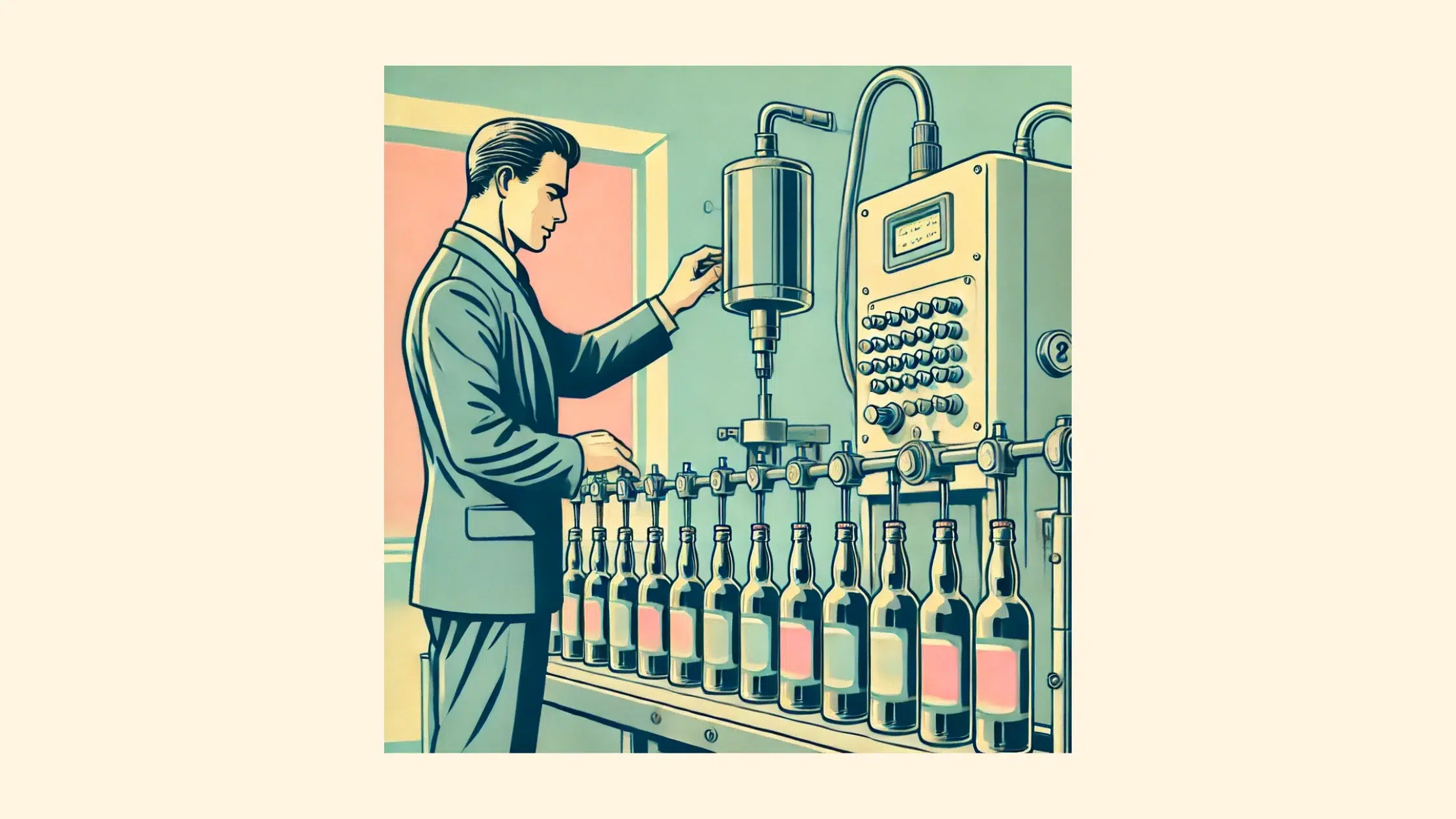

Steps in Whiskey Bottling

The whiskey bottling process unfolds through a series of meticulous steps, each designed to preserve the spirit’s quality and distinctive character. Initially, sanitization of the bottles ensures a clean slate, free from any contaminants that could affect the whiskey’s purity. Following this is the precision filling, a carefully controlled measure that guarantees consistency in every bottle, upholding the brand’s promise of uniformity.

Next, secure sealing acts as the guardian of the whiskey’s integrity, preventing oxidation and contamination that could compromise its complex flavor profile. The process concludes with accurate labeling, a critical step that conveys essential product information to the consumer and solidifies the brand’s image in the marketplace.

Each of these steps is underscored by stringent quality control checks, ensuring that the whiskey that reaches enthusiasts is nothing short of exceptional, reflecting the distillery’s unwavering dedication to craftsmanship.

Sanitization of Bottles

The bottling journey begins with sanitization, a non-negotiable step that ensures each bottle is pristine, eliminating any potential for contamination. This process safeguards the whiskey’s integrity and flavor profile, setting the stage for a flawless product.

Precision Filling

Precision filling follows, a step where meticulous attention to volume is paramount. This precision guarantees that each bottle holds the exact amount of whiskey, upholding the distillery’s reputation for consistency and quality in every pour.

Secure Sealing

Next is secure sealing, which is crucial for maintaining the whiskey’s aroma and taste. An airtight seal prevents oxidation and contamination, ensuring that the whiskey remains as intended from the moment it is bottled until it reaches the glass.

Accurate Labeling

Concluding the process is accurate labeling, which is about more than compliance; it’s a commitment to transparency and brand storytelling. Each label is meticulously applied to convey the whiskey’s origin, age, and character, allowing aficionados to connect with the spirit’s heritage and craftsmanship.

Types of Whiskey Bottles

Whiskey bottles are as diverse as the spirits they hold, each type serving both function and form. Standard glass bottles are ubiquitous, favored for their robustness and the way they showcase the whiskey’s hue. These bottles are the industry’s backbone, ensuring the spirit’s visual appeal and protection.

Conversely, decorative and limited-edition bottles stand as the jewels of the whiskey world. They are often crafted with intricate designs, serving as collectibles and markers of special occasions or premium batches. These bottles not only serve as vessels for the whiskey but also as expressions of the brand’s creativity and status.

The selection of a bottle type is more than a practical consideration; it’s a strategic branding decision that can influence the consumer’s perception and enhance the sensory experience of enjoying whiskey.

Standard Glass Bottles

Standard glass bottles form the cornerstone of whiskey presentation, valued for their transparency and resilience. They offer an unobstructed view of the whiskey’s color and consistency, key factors in the consumer’s selection process. These bottles are a testament to functionality, ensuring the whiskey is presented with reliability and integrity.

Decorative and Limited-Edition Bottles

For those seeking the extraordinary, decorative and limited-edition bottles offer a touch of exclusivity and artistry. These bottles are often synonymous with celebration and rarity, making them coveted pieces for collectors and enthusiasts. They not only preserve the whiskey’s quality but also reflect the distillery’s commitment to innovation and legacy.

Aging’s Impact on Whiskey

Aging is the alchemical process that fundamentally alters whiskey, imbuing it with richness and sophistication. As whiskey matures in barrels, it undergoes a metamorphosis, with the wood playing a crucial role in shaping its flavor profile. Elements like vanilla, caramel, and spice emerge, a testament to the cask’s influence.

The environment, including the climate and the warehouse conditions, also affects the aging process, contributing to the whiskey’s character. The interplay between these factors results in a spirit that is far more than the sum of its parts, offering a complexity that can only be achieved with time. Aging is not just a period of waiting—it’s an essential chapter in the whiskey’s story, where character is crafted and depth is developed.

Flavor Complexity Development

The journey of flavor complexity development is at the heart of whiskey’s aging process. Over time, the spirit undergoes a transformation, evolving a multilayered flavor profile. This intricate development is the essence of a well-aged whiskey, offering a symphony of tastes that range from subtle undertones to bold notes, delighting the palate with its depth and variety.

Wood’s Influence on Taste

The wood of the barrel plays a pivotal role in defining whiskey’s flavor. Its influence extends beyond mere containment; it actively imparts distinctive notes to the spirit. The type of wood, its level of charring, and its previous use (such as sherry or bourbon casking) contribute to a unique flavor signature. This is where vanilla, oak, fruit, and spice nuances are coaxed into the whiskey, creating its unmistakable character.

Bottling Regulations

Bottling regulations serve as the backbone of the whiskey industry’s commitment to quality and authenticity. These regulations establish the minimum alcohol by volume (ABV) that defines whiskey, creating a uniform standard for producers and consumers alike. Mandatory labeling content is also closely monitored, ensuring that each bottle provides clear information about the whiskey’s origin, age, and distillation.

Region-specific rules add another layer of specificity, particularly for whiskies with protected designations like Scotch or Bourbon. These rules uphold the traditions and standards that give these spirits their unique identity. Adherence to these regulations is essential, as it not only maintains the industry’s integrity but also reinforces the consumer’s confidence in the whiskey they choose to enjoy.

Alcohol by Volume (ABV) Limits

Alcohol by volume (ABV) limits are critical regulatory measures that ensure whiskey is bottled at an appropriate strength. These limits confirm the spirit’s potency and consistency, meeting both the legal criteria and the expectations of whiskey enthusiasts.

Mandatory Labeling Content

Mandatory labeling content is a cornerstone of consumer protection in the whiskey industry. It requires that labels accurately disclose essential information such as the whiskey’s ABV, origin, and age, fostering transparency and trust between the distillery and the consumer.

Region-Specific Rules

Region-specific rules are tailored to preserve the unique characteristics of whiskeys from distinct locales. These rules mandate specific production and aging processes for whiskeys with geographical indications, ensuring the authenticity and integrity of spirits like Scotch and Bourbon.

Bottling Technology’s Role

Bottling technology is a linchpin in the whiskey industry, driving efficiency and ensuring precision in the bottling process. Automated bottling lines represent a leap forward, consistently filling bottles with the exact volume of whiskey, crucial for upholding the consistency that consumers rely on. This technology also secures consistent fill levels, a vital quality control measure, while significantly reducing the risk of contamination—a testament to its importance in maintaining the revered standards of whiskey production.

Automated Bottling Lines

Automated bottling lines represent a quantum leap in whiskey production, providing unmatched precision and efficiency. These systems ensure that every bottle is filled with the exact measure of whiskey, essential for preserving the spirit’s quality and consistency.

Consistent Fill Levels

The use of automation guarantees consistent fill levels, a critical aspect of quality assurance. This uniformity is not just about aesthetics; it’s about ensuring each bottle contains the proper volume of whiskey, delivering on the brand’s promise of consistency.

Reduced Contamination Risk

Automation also brings a significant reduction in contamination risk. Advanced bottling systems are designed to minimize exposure to potential contaminants, safeguarding the whiskey’s purity and flavor integrity throughout the bottling process.

Packaging’s Role in Bottling

Packaging plays a crucial role in the whiskey bottling process, extending beyond mere containment to become a vital component of the brand’s narrative. It offers physical protection, ensuring that the whiskey remains unscathed from distillery to glass. The packaging also acts as a visual representation of the brand identity, with designs that range from classic elegance to bold modernity, resonating with consumers’ tastes and preferences.

Furthermore, the packaging is a bearer of information, with labels meticulously detailing the whiskey’s origin, age, and tasting notes. This aspect of packaging is not just informative but also contributes to the storytelling that enriches the consumer’s experience. Through thoughtful design and strategic messaging, packaging significantly influences the desirability and perception of the whiskey within.

Physical Bottle Protection

The physical protection of whiskey bottles is paramount, ensuring that the spirit is shielded from environmental factors that could compromise its integrity. Robust packaging is designed to uphold the whiskey’s quality and flavor, from the moment it leaves the distillery to its final destination.

Brand Identity Conveyance

Packaging acts as a silent yet powerful ambassador of the brand’s identity. Every element, from shape to color, is a deliberate choice that communicates the distillery’s story and values, resonating with the consumer and reinforcing the brand’s image in the marketplace.

Informative Label Design

Informative labels serve as a direct communication channel with the consumer, offering essential insights into the whiskey’s age, origin, and tasting profile. An effectively designed label is not just informative but also an invitation to explore the whiskey’s unique character and heritage.

Quality Control in Bottling

Quality control is the cornerstone of the whiskey bottling process, integral to maintaining the spirit’s excellence and consistency. It begins with bottle integrity checks, a critical step to ensure each bottle is flawlessly sealed and free from imperfections that could compromise the whiskey’s quality.

Batch tasting protocols are meticulously followed to confirm that every batch aligns with the distillery’s flavor standards, preserving the brand’s signature taste. Monitoring environmental conditions is also crucial, as it helps maintain the optimal setting for the whiskey’s final stages of production, ensuring that the quality remains uncompromised from distillery to dram.

Bottle Integrity Checks

Bottle integrity checks are a fundamental aspect of ensuring that each whiskey bottle is flawlessly crafted and sealed. These checks are designed to prevent any potential leakage and to protect the whiskey from external influences that could degrade its taste and longevity.

Batch Tasting Protocols

Batch tasting protocols are a meticulous process conducted by seasoned experts, who ensure that each batch of whiskey matches the brand’s signature flavor profile. This consistency is key to the brand’s reputation and customer satisfaction.

Environmental Condition Monitoring

Environmental condition monitoring is essential for preserving the whiskey’s quality during the bottling phase. By keeping a close watch on temperature and humidity, distilleries can prevent any environmental factors from affecting the whiskey’s character and purity before it is sealed and sent to the market.