The world of whiskey is a realm of rich flavors, enticing aromas, and smooth textures, all of which are the result of a meticulous production process. At the heart of this process lie two crucial stages: distillation and filtration. Distillation is the art of separating and intensifying the alcohol content from the fermented mixture, while filtration is the science of refining the whiskey by removing certain elements that could alter its taste and clarity. In this article, we’ll embark on a journey to explore the principles, impacts, and techniques of distillation and filtration in whiskey production. This exploration aims to enlighten whiskey enthusiasts, helping them deepen their understanding of the intricate art that is whiskey production.

Principle of Distillation

The transformation of a simple brew into the complex spirit we know and love as whiskey is largely due to the process of distillation. The principle of distillation hinges on the varying boiling points of the liquid components within the fermented mixture, or wash.

Imagine the scene: the wash is heated, and as the temperature rises, the alcohol and other lower boiling point elements start to evaporate, leaving behind water and other substances with higher boiling points. These evaporated elements, known as vapors, are then directed into a condenser. Here, they cool down and return to their liquid state, forming a new liquid with a higher concentration of alcohol, aptly named ‘distillate’.

But not all distillate is created equal. The first and last portions, known as the ‘heads’ and ‘tails’, contain elements that are less desirable and are often discarded or redistilled. The ‘heart’, the middle segment, is the gold standard of distillate, brimming with high-quality flavors and aromas. This selective process ensures only the best distillate contributes to the maturation process, leading to the creation of superior quality whiskey.

Impact of Distillation on Whiskey

Distillation plays a pivotal role in shaping the whiskey’s personality. It’s not just a step in the production process, but an art form that crafts the final product’s essence. The distillation process influences the whiskey in three primary areas: strength, purity, and flavor.

Firstly, distillation boosts the spirit’s alcohol strength, which directly affects the whiskey’s character. For instance, a spirit with a higher alcohol concentration often results in a lighter, more nuanced whiskey profile.

Secondly, distillation purifies the fermented wash by removing impurities. The careful selection of heads, hearts, and tails during distillation can control the presence of methanol, fusel oils, and other compounds. These elements significantly impact the whiskey’s purity and ultimately its profile.

Finally, the flavor of the whiskey is significantly influenced by distillation. Factors such as the type of still used, the heating method, the cut points, and the number of distillation stages all contribute to the whiskey’s unique flavor. Each distillery employs its distinctive distillation methods, creating an exclusive flavor profile that sets their whiskey apart.

In essence, distillation is a craft that shapes the whiskey’s very soul, making it an integral part of the production process.

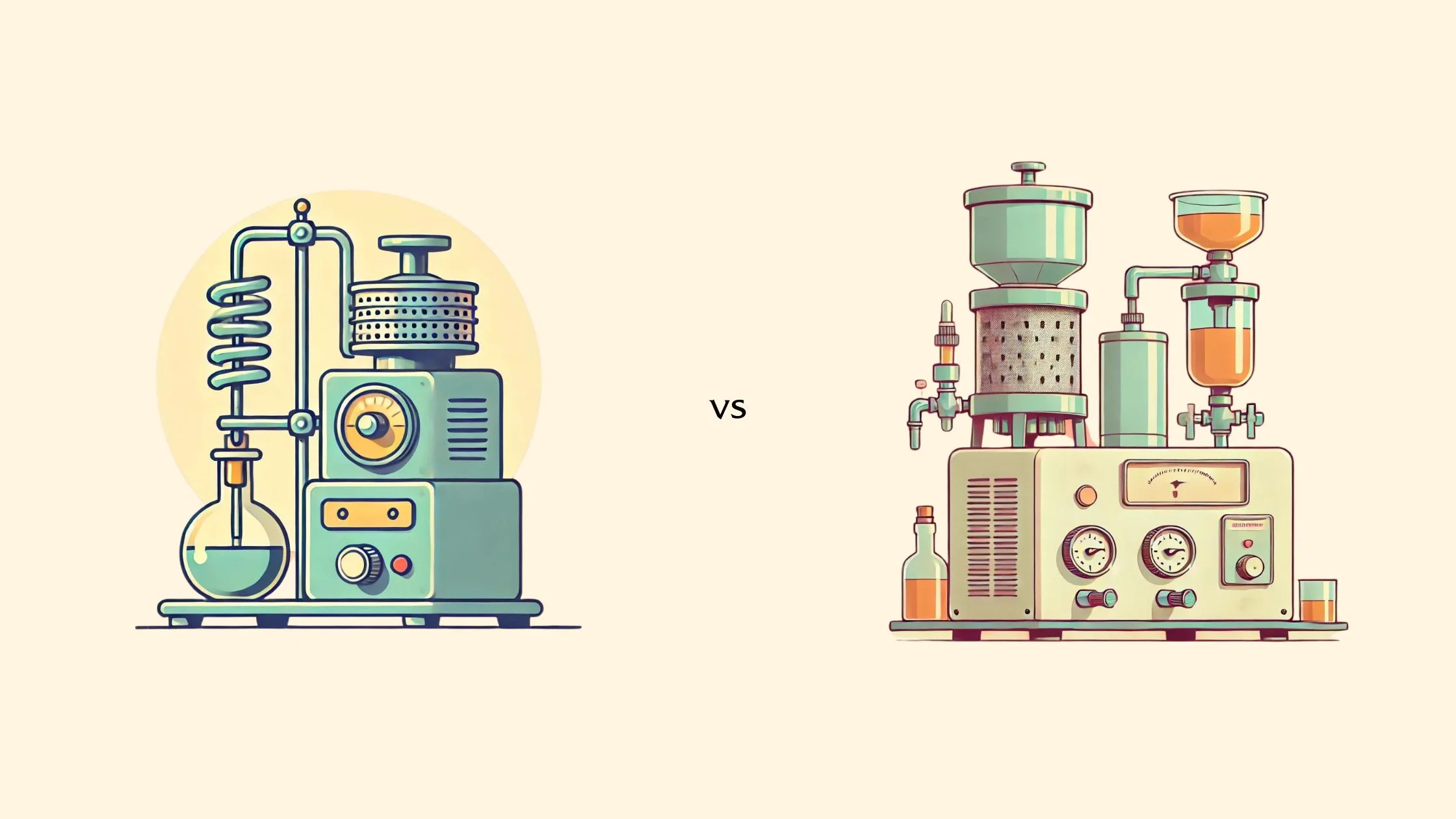

Distillation Techniques: Pot Still vs. Continuous Still

The art of distillation may follow a similar principle across the board, but the technique employed can significantly influence the whiskey’s characteristics. The two primary distillation techniques used in whiskey production are pot still distillation and continuous, or column still distillation. Each technique brings its unique advantages to the table, defining the final spirit’s subtleties and nuances.

Understanding these distillation techniques not only enriches our knowledge of whiskey production but also deepens our appreciation for the craftsmanship behind each whiskey bottle. Let’s delve deeper into these distillation methods in the subsequent sections, exploring their unique contributions to the world of whiskey.

Pot Still Distillation

Pot still distillation, a time-honored technique, is synonymous with the creation of single malt and Irish whiskeys. The process involves a large copper vessel, or pot still, which is used to distil the fermented wash. As the wash heats up, alcohol and flavor compounds evaporate due to their lower boiling points compared to water.

This method is typically a two-step process: the initial distillation (wash distillation) and a subsequent distillation (spirit distillation). The first step yields a low-strength distillate, referred to as ‘low wines.’ The second step further refines and strengthens the spirit, preparing it for maturation.

The pot still distillation process shines in its ability to preserve a wide spectrum of flavors. It allows for a high degree of manual control, which can be leveraged to create whiskeys with intricate and distinctive flavor profiles. Interestingly, the pot still’s type and shape can subtly influence the spirit’s character by affecting the interaction between the liquid and the copper. This interaction can impact the removal of sulfur compounds and the alcohol concentration in the vapor.

Despite its advantages, pot still distillation is labor-intensive and less efficient than its counterpart, continuous still distillation. This makes it a more expensive option, often favored by smaller-scale, craft distilleries.

Continuous Still Distillation

Continuous still distillation, also known as column or patent still distillation, is a modern, efficient, and industrialized method often used in American bourbon and grain whiskey production.

This technique operates on a principle of continuous distillation. The wash is fed into the still continuously, and the distillate is collected in the same manner, eliminating the need for separate distillation runs. The still, composed of two columns, uses steam to heat the wash. As the alcohol vapors ascend the column, they condense at different strengths at various levels (or plates) inside the still. This allows for a more precise separation of alcohol and other compounds, yielding a high-strength and pure distillate.

One of the significant advantages of continuous still distillation is its efficiency. Its continuous operation results in higher whiskey production volumes. Furthermore, the output strength can be adjusted, enabling distilleries to produce whiskeys of varying styles.

However, continuous still distillation may not capture the full range of flavors that pot still distillation can, as it tends to remove more impurities and congeners. The resulting whiskey is typically lighter with a cleaner taste profile, making it a preferred choice for those who enjoy softer and smoother spirits.

The Role of Filtration in Whiskey Production

Filtration, much like distillation, holds a significant position in the whiskey production process. This step is all about refining and purifying the whiskey before it’s ready for bottling. The filtration process can dramatically influence the final taste, clarity, and overall presentation of the whiskey. The choice to filter, and the filtration method used, can make a substantial difference in the whiskey’s final character. Let’s delve into the principles of filtration, its impact, and the various techniques used in whiskey production.

Principle of Filtration

In the realm of whiskey production, filtration is the act of eliminating certain undesirable residuals from the spirit post-distillation and maturation. The goal is to improve clarity, tweak flavor, and ensure stability in the final product. The whiskey is passed through a filter, which can be made of various materials such as charcoal, paper, or synthetic substances.

Filtration primarily targets solids and compounds like fatty acids, proteins, and esters. These substances can alter the texture, visual appeal, and to some degree, the flavor of the whiskey.

However, it’s crucial to understand that filtration isn’t a one-size-fits-all process for all whiskeys. Different whiskey styles necessitate different filtration methods. Some whiskeys may undergo rigorous filtration, others a gentle filtering, and some may not be filtered at all, beyond basic clarification methods to remove solid residue. This depends on the unique character that distillers aim to showcase in the final product.

Filtration’s primary role is to purify the whiskey, but it’s not without its drawbacks. While it eliminates undesirable elements, it can also potentially remove desirable flavors and aromas if not executed with care. Therefore, distilleries strive for a balance, crafting filtration procedures that maintain the spirit’s essence while enhancing its physical appearance and stability.

Impact of Filtration on Whiskey

Filtration plays a pivotal role in the whiskey production process, influencing not only the visual appeal but also the sensory experience of the final product. It primarily functions to eliminate impurities and residual solids that could compromise the clarity of the whiskey, thereby enhancing its aesthetic appeal. A clear, sparkling whiskey is often associated with superior quality by consumers.

The influence of filtration extends beyond the visual aspect, impacting the taste and texture of the whiskey as well. The process can modify the whiskey’s mouthfeel by eliminating certain components like fatty acids and esters. This removal can potentially result in a smoother whiskey, albeit possibly with a lighter body.

The effect of filtration on the taste of whiskey is a subject of ongoing debate. Some argue that it removes desirable flavor and aroma compounds, leading to a less vibrant spirit. Others, however, believe that it refines the whiskey by eliminating harsh elements and improving the balance of flavors.

The impact of filtration on a whiskey’s character is largely subjective and often aligns with individual consumer preferences. Some whiskey aficionados prefer the clean, pure flavors of filtered whiskeys, while others favor unfiltered whiskeys for their depth, robustness, and perceived authenticity.

Filtration Techniques: Chill and Charcoal Filtration

The method of filtration employed in whiskey production can greatly shape the final character of the spirit. Among the most commonly used techniques are Chill Filtration and Charcoal Filtration, each having a distinct effect on the whiskey’s appearance, texture, and flavor profile. In the subsequent sections, we will delve into these techniques, exploring their workings, their impacts on whiskey, and their prevalence in the industry.

Chill Filtration

The art of whiskey production often involves the use of chill filtration, a technique that primarily enhances the whiskey’s visual appeal and consistency. This method involves chilling the whiskey to approximately -10 degrees Celsius (-14F). At this temperature, certain compounds such as fatty acids, proteins, and esters precipitate and solidify, making them easier to filter out.

The result of this process is a whiskey that remains visually clear, even when cooled or diluted, eliminating the potential for a hazy appearance that can occur in non-chill filtered whiskeys. However, the use of chill filtration is not without controversy. Critics suggest that the process might eliminate elements that enhance the whiskey’s flavor and mouthfeel, potentially reducing its overall sensory complexity.

Despite this, many high-quality and popular whiskeys on the market today employ chill filtration, demonstrating that when used appropriately, it can yield superior results. The key lies in striking the right balance, a task each distillery undertakes to align with their unique flavor profiles and meet customer expectations.

Charcoal Filtration

Charcoal filtration, also known as the Lincoln County Process, is a unique method used in the production of Tennessee whiskey. This process sets Tennessee whiskey apart from its well-known counterpart, Bourbon. In this technique, freshly distilled whiskey is slowly filtered through about ten feet of sugar maple charcoal.

The charcoal’s expansive surface area acts like a sponge, absorbing impurities and specific compounds from the whiskey. This process can take anywhere from a few days to several weeks, depending on the desired flavor profile the distillery aims to achieve.

The impact of charcoal filtration on the final character of the whiskey is significant. It aids in creating a smoother, softer drink by eliminating residual compounds that may contribute to harsh or astringent flavors. Additionally, it imparts a subtle sweetness to the whiskey, a characteristic trait of Tennessee whiskey.

However, much like chill filtration, charcoal filtration has its critics. Some whiskey enthusiasts argue that it removes too many flavors, resulting in a less complex whiskey. Yet, when executed by skilled distillers, charcoal filtration can produce a whiskey that is smooth, flavorful, and uniquely distinctive.

Comparing Distillation and Filification in Whiskey Production

In the intricate world of whiskey production, distillation and filtration stand as two pillars, each playing a pivotal role in crafting the final product. These processes, though distinct in their functions, work in harmony to transform the raw grain into a refined spirit. The interplay between distillation and filtration is a fascinating dance of science and artistry, shaping the whiskey’s character and quality. Let’s explore this dynamic duo further, examining their unique roles and the points where their paths intersect and diverge.

Similarities and Differences

Despite their differing methodologies, distillation and filtration share a common goal: the creation of a superior whiskey. Both processes leave an indelible mark on the spirit, influencing its taste, aroma, texture, and visual allure. Moreover, both distillation and filtration are adaptable, allowing distillers to tweak the techniques to achieve their desired whiskey profiles.

However, their roles in the whiskey production journey are distinct. Distillation is the alchemical stage where the magic happens – the fermented mash transforms into alcohol. This process not only concentrates the alcohol but also allows the flavor compounds to express themselves, adding complexity to the spirit.

Filtration, conversely, is the refining stage that follows distillation and aging. It doesn’t contribute to alcohol creation but enhances the final product by purging impurities and fine-tuning the whiskey’s taste and appearance. The application of filtration can vary significantly across different whiskeys, even within the same category, adding another layer of complexity to the process.

In essence, distillation and filtration are two sides of the same coin, each playing a unique yet equally important role in whiskey production. Distillation lays the foundation, shaping the whiskey’s core character, while filtration polishes and refines it. Together, they contribute to the rich tapestry of flavors and aromas that make up the diverse world of whiskey.