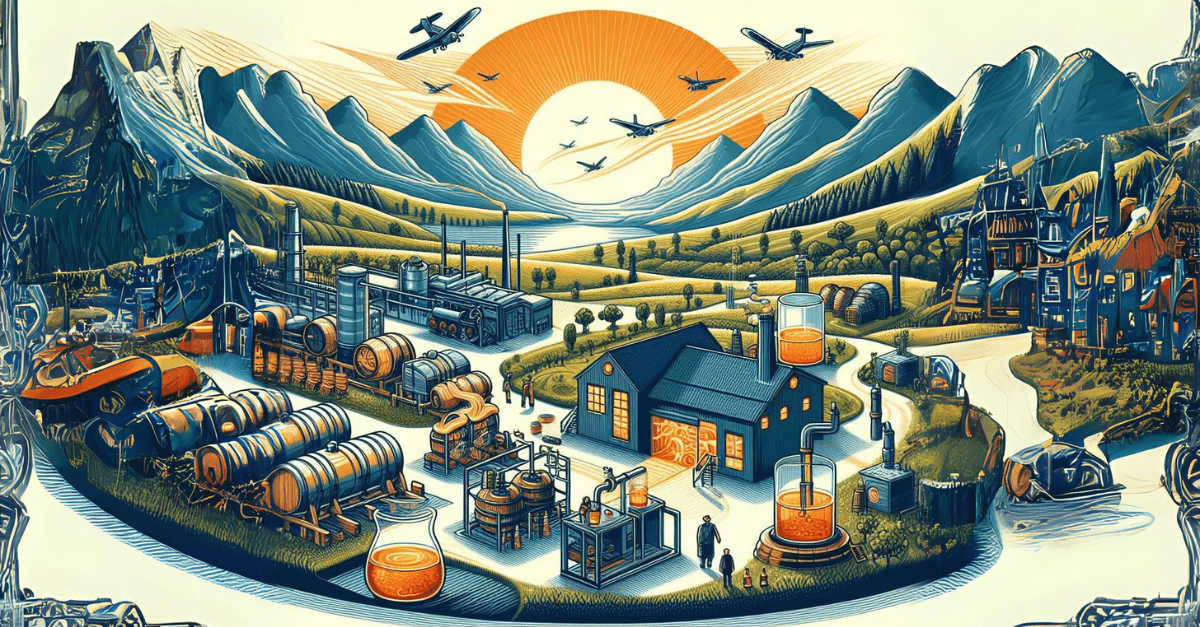

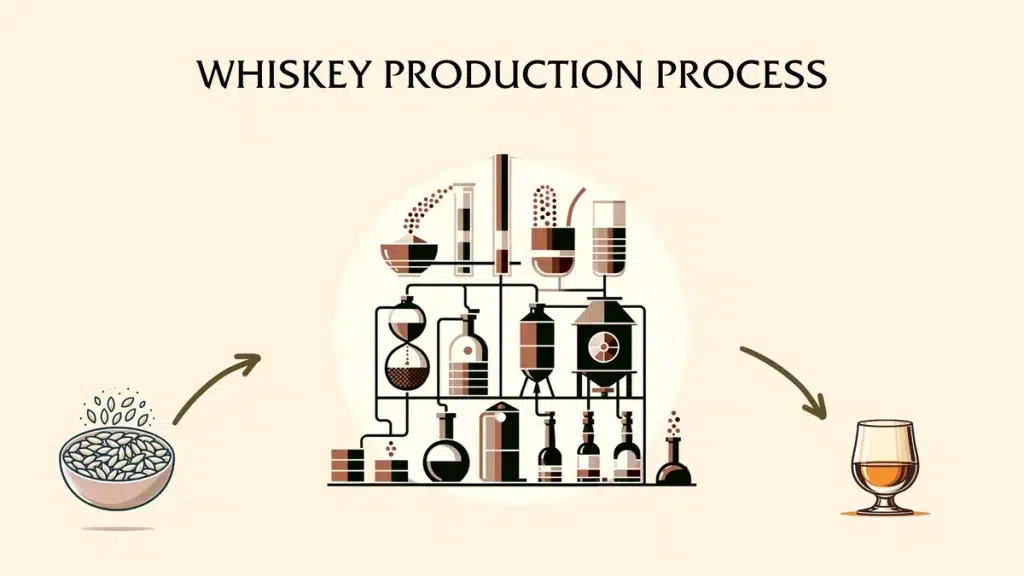

Whiskey production is a meticulous process that transforms simple grains into complex spirits through a series of carefully controlled steps. The journey begins with malting, where grains are germinated and dried to unlock sugars essential for fermentation. In mashing, these sugars are extracted and combined with yeast, which ferments the mixture into an alcohol-rich wash. Distillation then concentrates the alcohol and refines the flavors, while aging in wooden barrels imbues the whiskey with depth, character, and a golden hue. The final product is proofed to the desired strength, bottled, and then ready to be savored by enthusiasts around the world, each bottle a narrative of its origin, ingredients, and the time-honored traditions of its craft.

What is the whiskey malting process?

The malting process is a transformative phase in whiskey production where the potential of grains is unlocked, setting the stage for flavor development. It begins with soaking the grains, typically barley, in water to initiate germination. This crucial step activates enzymes which are instrumental in converting the grain’s starches into fermentable sugars. After germination, the grains are dried in a kiln, halting growth and locking in the desired enzyme content.

The drying phase can also introduce additional flavors, especially if peat is used, imparting a smoky characteristic to the final spirit. Once dried, the malted barley forms the foundational component of the mash bill, ready for the next stages of mashing and fermentation. The malting process, therefore, not only contributes to the whiskey’s eventual flavor profile but also reflects the distiller’s craftsmanship and the regional attributes of the whiskey.

- Which grains are best for whiskey?

The best grains for whiskey are those that provide the desired flavor profile and adhere to specific style regulations. Barley is prized for its rich enzymes and is essential for single malt Scotch, while corn is the cornerstone of bourbon, imparting a sweeter taste. Rye adds a spicy note and is central to rye whiskey, and wheat offers a softer, more mellow flavor, often used in wheated bourbons. - How does grain quality affect whiskey?

Grain quality profoundly impacts the whiskey’s final character. High-quality grains ensure optimal sugar content for fermentation and contribute to the complexity of the whiskey’s flavor. Poor quality grains can result in off-flavors and inefficiencies during production, underscoring the importance of selecting the best possible ingredients for exceptional whiskey. - What steps are involved in malting whiskey?

The malting process for whiskey involves three primary steps: steeping the grains in water to initiate germination, allowing the grains to germinate and develop enzymes, and drying the germinated grains in a kiln to halt the process and produce malted barley. Each step is carefully controlled to optimize enzyme production and flavor development. - How long to soak grains for whiskey?

Soaking grains for whiskey, also known as steeping, typically lasts one to three days. This duration is sufficient to awaken the grain’s enzymes without oversaturating or causing premature germination, striking a balance that prepares the grains for optimal malting. - What temperature is best for whiskey germination?

The ideal temperature for whiskey germination is between 60-70°F (15-21°C). This range encourages steady growth and enzyme activity without risking the development of unwanted bacteria or fungi, ensuring a healthy start to the malting process. - What kilning techniques are used for whiskey?

Kilning techniques for whiskey vary depending on the desired flavor outcome. Traditional kilns may use hot air for a gentle drying effect, while peat-fired kilns impart a distinctive smoky flavor. The temperature and duration of kilning are finely tuned to preserve the enzymes while adding character to the malt.

How is whiskey mash made?

Whiskey mashing is a precise blend of science and tradition, where the chosen grains are ground into a coarse meal and then mixed with hot water to form a mash. This process, known as mashing, activates enzymes that break down starches into fermentable sugars. The temperature and ratio of water to grain are critical, as they dictate the efficiency of sugar extraction and the overall quality of the mash. Once the sugars are released and the mixture has cooled to the optimal temperature, yeast is introduced to begin fermentation. The mash thus becomes the lifeblood of whiskey production, its quality setting the tone for the potency and flavor profile of the distilled spirit.

- What is a whiskey mash bill?

A whiskey mash bill is the specific recipe of grains used to produce whiskey, acting as a blueprint for its flavor. It details the precise proportions of barley, corn, rye, wheat, or other grains, each chosen for their contribution to the final spirit’s taste and character. - How do grain proportions impact whiskey flavor?

Grain proportions in a mash bill directly influence whiskey flavor, with each grain offering unique taste notes. Corn brings sweetness, barley adds a nutty essence, rye introduces spiciness, and wheat contributes a soft, mellow touch. The interplay of these grains shapes the whiskey’s complexity and balance. - Can mash bill affect whiskey taste?

Absolutely, the mash bill can significantly affect whiskey taste. The selection and ratio of grains determine the dominant flavors, from the sweetness of corn to the boldness of rye, ultimately defining the whiskey’s distinct profile and sensory appeal. - What mashing techniques are used in whiskey making?

Mashing techniques in whiskey making involve carefully controlling the temperature and water addition to optimize the conversion of starches into sugars. Techniques vary from single to multiple infusions, each designed to maximize the efficiency of sugar extraction from the specific grain mix. - How does enzymatic conversion work in whiskey?

Enzymatic conversion in whiskey occurs during mashing, where natural enzymes in the malted grains break down complex starches into simpler sugars. This conversion is crucial for fermentation, as yeast feeds on these sugars to produce alcohol. - How is sugar extracted during whiskey mashing?

Sugar is extracted during whiskey mashing by soaking the ground grains in hot water, which activates the enzymes to convert starches into sugars. The mash is then held at specific temperatures to ensure maximum sugar release before cooling for fermentation. - What is a mash tun in whiskey production?

A mash tun in whiskey production is a large vessel where the mashing process takes place. It’s designed to mix hot water with the ground grains, facilitate enzymatic conversion, and allow the separation of the liquid wort from the spent grains.

What is the whiskey fermentation process?

The whiskey fermentation process is where the alchemy of turning sugar into alcohol happens, a critical transformation in whiskey production. After mashing, the sweet liquid known as wort is cooled and transferred to fermentation vessels, where yeast is added. This yeast feasts on the sugars, producing alcohol and a variety of flavor compounds in a process that can last from a few days to over a week. The environment, yeast strain, and fermentation duration are meticulously controlled to develop the desired flavor profile and alcohol content, resulting in a liquid called ‘wash’ that is ready for distillation. This stage is not just about alcohol creation; it’s where the foundational flavors of the whiskey begin to take shape, influenced by the unique characteristics of the yeast and the fermentation conditions.

Fermentation is both an art and a science, requiring a harmonious balance between precision and intuition. The choice of yeast and the fermentation conditions are as crucial as the grain selection, each decision echoing through the final taste of the whiskey. It’s a natural yet controlled process, where the distiller’s expertise ensures that the right environment is provided for the yeast to thrive. The end product of fermentation, the wash, carries the weight of potential, embodying the raw essence that will, through distillation, mature into the complex spirit known as whiskey.

- Which yeast is best for whiskey fermentation?

The best yeast for whiskey fermentation is one that complements the desired flavor profile and performs well under the distillery’s specific conditions. Distillers often choose strains of Saccharomyces cerevisiae for their reliable fermentation rates and ability to produce a rich array of congeners, which are flavor compounds that contribute to the whiskey’s complexity. - How does yeast affect whiskey flavor?

Yeast significantly affects whiskey flavor by producing a spectrum of congeners during fermentation, including alcohols, esters, and acids. Each yeast strain has a unique profile, influencing the whiskey’s final taste with fruity, floral, spicy, or buttery notes. The choice of yeast is a pivotal decision that shapes the spirit’s character long before it reaches the barrel. - What’s the difference between open and closed fermentation?

The difference between open and closed fermentation lies in the exposure to the environment. Open fermentation allows the mixture to interact with ambient microflora, potentially introducing unique, location-specific flavors. In contrast, closed fermentation occurs in sealed vessels, providing a controlled environment that can lead to a more consistent and predictable flavor outcome. - How to monitor whiskey fermentation?

To monitor whiskey fermentation, distillers measure specific gravity, temperature, and pH levels throughout the process. These indicators help track the yeast’s activity and sugar conversion, ensuring the fermentation is progressing as intended. Modern technology allows for real-time monitoring and adjustments, guaranteeing optimal conditions for flavor development and alcohol production.

What methods are used for whiskey distillation?

Whiskey distillation employs two primary methods: pot still and column still distillation. Pot still distillation, a traditional approach, involves heating the fermented wash in a large, copper kettle where the alcohol vapors rise, condense, and are collected in a purer form. This method is revered for its ability to produce a full-bodied spirit with rich flavors. Column still distillation, on the other hand, uses a tall, multi-level column to continuously distill the wash, resulting in a higher alcohol content and a lighter, cleaner spirit. Both methods are integral to defining the whiskey’s character, with the choice of distillation technique influencing the final product’s taste, strength, and smoothness. The distiller’s mastery over these methods ensures the whiskey embodies the desired balance of purity and flavor complexity, essential for crafting a distinguished and enjoyable spirit.

The intricacies of whiskey distillation are not merely about separating alcohol from water; they are a craft that shapes the soul of the whiskey. Pot still distillation, often used for single malt Scotch and Irish whiskeys, allows for a rich interplay of flavors, as the shape of the still and the number of distillations create a unique profile. Column stills, preferred for producing American bourbon and rye, offer efficiency and consistency, allowing for a continuous distillation process that can be fine-tuned to achieve the desired lightness and clarity.

Each method has its own set of variables, from the cut points that determine which fractions of the distillate are kept to the material of the stills themselves, which can influence the spirit’s final flavor. The distiller’s deep understanding of these methods and their nuances is what turns the raw wash into a whiskey that is both an expression of its ingredients and a testament to the art of distillation.

- What is pot still whiskey distillation?

Pot still whiskey distillation is a traditional method where the wash is heated in a large, onion-shaped copper vessel. The heat causes alcohol and other compounds to vaporize, ascend through the still’s neck, and then condense back into liquid form. This process is typically run in batches and is known for yielding a spirit with a rich, complex flavor profile due to the less efficient separation of alcohol from other congeners. - How does column still distillation differ from pot still?

Column still distillation differs from pot still in its design and operation, utilizing a tall, vertical column that allows for continuous distillation. The wash enters the column, and as it rises, it encounters a series of plates or trays that progressively increase the alcohol purity. This method is more efficient than pot still distillation, producing a higher-proof spirit with a lighter, cleaner taste, often preferred for blending or creating smoother whiskeys. - What are cut points in whiskey distillation?

Cut points in whiskey distillation are the moments during the process when the distiller separates the desirable middle portion of the distillate, known as the ‘hearts,’ from the less desirable ‘heads’ and ‘tails.’ These cuts are crucial for influencing the whiskey’s final flavor, as heads contain volatile compounds and tails hold heavier oils and fusel alcohols. - What are heads, hearts, and tails in whiskey?

Heads, hearts, and tails are terms that describe the different fractions of alcohol collected during distillation. ‘Heads’ are the first vapors to condense, containing unwanted compounds that can affect the taste and quality. ‘Hearts’ are the desired middle cut with the ideal balance of flavors and alcohol purity. ‘Tails’ are the last vapors, which include heavier, often undesirable compounds. The skillful separation of these fractions is essential to crafting a high-quality whiskey.

How does whiskey age?

Whiskey aging is the process where distilled spirits mature, developing depth and complexity within the confines of a barrel. This transformative period begins once the clear, potent distillate is placed into wooden casks, typically oak, which act as catalysts for change. Over time, the interaction between the whiskey and the wood’s cellulose, lignin, and tannins imparts rich colors, robust flavors, and smooth textures.

The aging environment plays a pivotal role, with factors such as temperature, humidity, and even the cask’s location within the warehouse influencing the spirit’s maturation rate and character. As the seasons change, the whiskey expands and contracts within the barrel, allowing it to breathe in the wood’s essence and the surrounding air. This natural cycle of oxidation and evaporation, often referred to as the “angel’s share,” further refines the whiskey, ensuring that each bottle tells a story of time and patience.

The duration of whiskey’s aging is a dance with time, where each year imparts additional layers of subtlety and sophistication to the spirit. The choice of barrel—new or used, charred or toasted—adds another dimension, introducing flavors from vanilla and caramel to spicy and fruity notes. The aging process is not merely passive; it’s an active evolution, a complex interplay of chemistry and craftsmanship that transforms the raw distillate into a beverage celebrated for its rich tapestry of tastes and aromas. Mastery of the aging process is a hallmark of the finest distillers, a testament to their ability to harness time itself in the pursuit of the perfect whiskey.

- What types of barrels are used for whiskey aging?

Various types of barrels are used for whiskey aging, each imparting distinct characteristics to the spirit. The most common are American oak barrels, which lend sweet vanilla tones, and European oak barrels, known for their spicy and fruit-forward notes. Additionally, whiskey makers may use barrels that previously held sherry, port, or wine to introduce complex, nuanced flavors. - Difference between American and European oak barrels?

The difference between American and European oak barrels lies in their wood grain and natural flavor compounds. American oak has a tighter grain and typically imparts sweeter flavors like vanilla and caramel, while European oak has a looser grain, often contributing robust, spicy notes and a darker color to the whiskey. - How does previous barrel use affect whiskey?

Previous barrel use significantly affects whiskey by introducing layers of flavors that were absorbed by the wood from its initial contents. Barrels that once held sherry, for instance, can add dried fruit and nutty flavors, while ex-bourbon barrels might contribute subtle sweetness and hints of coconut. - How does climate impact whiskey aging?

Climate plays a crucial role in whiskey aging, as temperature fluctuations cause the wood to expand and contract, allowing the whiskey to interact more with the barrel. A warmer climate accelerates aging, leading to a faster maturation process, while cooler climates slow it down, often resulting in a more gradual flavor development. - What is the optimal time for whiskey maturation?

The optimal time for whiskey maturation varies depending on the desired flavor profile, barrel type, and aging environment. While some whiskeys reach maturity in just a few years, others may require decades to develop their full character. Distillers must carefully balance time to achieve the intended complexity and quality of the whiskey.

What is involved in the whiskey bottling process?

The whiskey bottling process is the final stage in whiskey production, where the spirit is prepared for consumption. This phase involves proofing, where water is added to the matured whiskey to achieve the desired alcohol content, ensuring consistency and balance in flavor. The whiskey is then filtered to remove any impurities and sediment, preserving clarity and smoothness. Next, the liquid is transferred into bottles, which are sealed to maintain quality and prevent contamination. Labeling is also a critical step, providing consumers with information about the whiskey, including its type, age, and origin. The bottling process must adhere to stringent standards to ensure that the whiskey’s journey from barrel to bottle captures the essence of its character, ready to be enjoyed by aficionados worldwide.

Beyond the technical aspects, the bottling process is also where the distillery’s brand is conveyed through packaging design and presentation. The bottle shape, label artwork, and closure type are carefully selected to reflect the whiskey’s identity and appeal to consumers’ preferences. This stage is not just about precision and quality control; it’s a culmination of the distillery’s craft, where the visual and tactile elements of the bottle meet the sensory experience of the whiskey, creating a cohesive narrative that resonates with whiskey lovers.

- How is whiskey proofing and dilution done?

Whiskey proofing and dilution are done by adding water to the cask-strength spirit to lower the alcohol by volume (ABV) to a desired level. This process is carefully measured and controlled to ensure the whiskey’s flavor profile remains intact while meeting legal and brand standards for ABV. - How to adjust whiskey ABV before bottling?

To adjust whiskey ABV before bottling, distillers calculate the precise amount of water needed based on the initial ABV and the target strength. The water is gradually blended with the whiskey, and the ABV is continuously monitored to ensure accuracy and consistency across batches. - What types of bottles are used for whiskey?

Various types of bottles are used for whiskey, ranging from standard round and square shapes to custom-designed decanters. The choice depends on the brand’s image, the whiskey’s price point, and the target market. Glass is the preferred material for its inert properties and ability to preserve the whiskey’s quality. - What should be considered in whiskey packaging design?

Whiskey packaging design should consider aesthetics, brand identity, functionality, and consumer appeal. The label should provide essential information and convey the whiskey’s story, while the packaging should protect the bottle and ensure its integrity from distillery to glass. - How is quality control maintained in whiskey bottling?

Quality control in whiskey bottling is maintained through rigorous testing and inspection at every stage. This includes verifying the ABV, ensuring the absence of contaminants, checking the integrity of seals and closures, and confirming that labeling is accurate and compliant with regulations.

How is whiskey sensory evaluation conducted?

Whiskey sensory evaluation is a systematic process that assesses the spirit’s aroma, taste, and finish to ensure quality and consistency. Expert tasters, often called nosers, use their refined palates to detect a wide range of flavors and aromas, from the basic to the subtle. The evaluation is typically conducted in a controlled environment to prevent any external factors from influencing the tasters’ perceptions.

A standard nosing glass is used to concentrate the whiskey’s bouquet, and the spirit is often diluted with water to reduce the alcohol’s impact on the senses, allowing a more accurate assessment of its characteristics. Sensory evaluation is not just about detecting flaws; it’s an art that appreciates and understands the whiskey’s complexity, balance, and the harmony of its flavors, providing invaluable feedback that can shape future production.

This meticulous evaluation extends beyond individual expertise, often involving a panel of tasters to ensure a comprehensive analysis. The panel’s collective experience and diverse palates contribute to a more objective assessment, capturing the full spectrum of the whiskey’s sensory profile.

Descriptive language and a standardized scoring system are employed to document the nuances, ensuring that each note, from the smoky peat to the sweet caramel, is accounted for. Sensory evaluation is thus a cornerstone of the whiskey-making process, a blend of science and sensory artistry that upholds the spirit’s legacy and guides its evolution.

- What do whiskey tasting panels look for?

Whiskey tasting panels look for a harmonious balance of flavors, aromas, and the overall quality of the spirit. They assess the whiskey’s appearance, nose, palate, and finish, evaluating characteristics such as clarity, complexity, and smoothness. Panels also look for any off-notes or inconsistencies that could indicate faults in production, ensuring that each bottle meets the brand’s standards and provides the desired sensory experience. - What chemical analysis is done on whiskey?

Chemical analysis on whiskey can include gas chromatography and mass spectrometry to identify and quantify the various compounds present in the spirit. These analyses help distillers understand the whiskey’s flavor profile on a molecular level, detect any impurities, and ensure consistency across batches. Additionally, chemical analysis can be used to verify age claims and authenticate the whiskey’s origin. - What are the legal standards for whiskey production?

The legal standards for whiskey production vary by country and region, but they typically define the types of grains used, minimum aging periods, and allowable additives. For example, bourbon must be made from at least 51% corn and aged in new charred oak barrels, while Scotch whisky must be distilled in Scotland and aged for at least three years. These regulations ensure product integrity, protect consumer interests, and uphold the traditions and reputation of each whiskey category.